PET met is a polyester film metalized with aluminum powder. Polyester films are already characterized by high strength and surface hardness. However, especially with regard to diffusion density, the properties of the film can be improved by using aluminum powder.

The advantages of PET met are in particular higher tensile strength and lower production costs compared to conventional aluminum foils. In composites produced from vaporized aluminum, the possible processing speeds are significantly higher than in aluminum foil.

Packaging, especially for foods that are sensitive to moisture or oxidation, such as coffee or instant soups.

Relative vapor barrier in building insulation.

Tapes and labels with high chemical and heat resistance for vehicle technical or outdoor areas.

Really just a little bit of aluminum

The thickness of the aluminum layer in PET is very small, so the unit Ångström, which is derived from the atomic diameter, is often used instead of the measurement in μm (micrometer).

Therefore, measurements in Ångströms can be viewed as the corresponding number of atoms stacked directly on top of each other. Of course, this does not reflect the actual physical conditions, but only illustrates the extremely thin thickness of the metal support layer.

Absolute value and comparison of the layer thickness of metalized PET film

A typical range for the thickness of the aluminum layer is about 3 to 50 nm for metalized PET films of about 30 Å-500 Å. In contrast, pure gold can be reshaped into a thin gold foil of 2000 Å. At this thickness, the gold is already slightly translucent and appears green in the light.

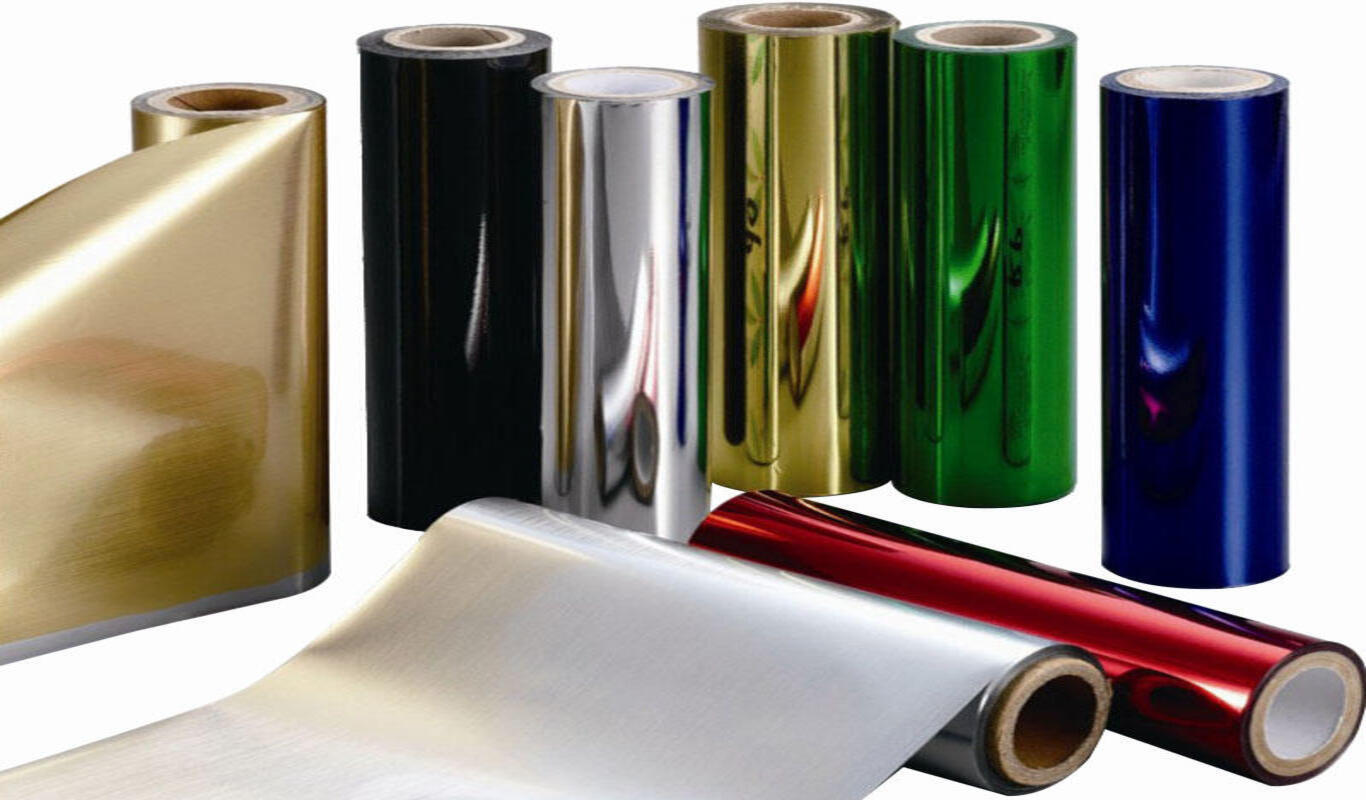

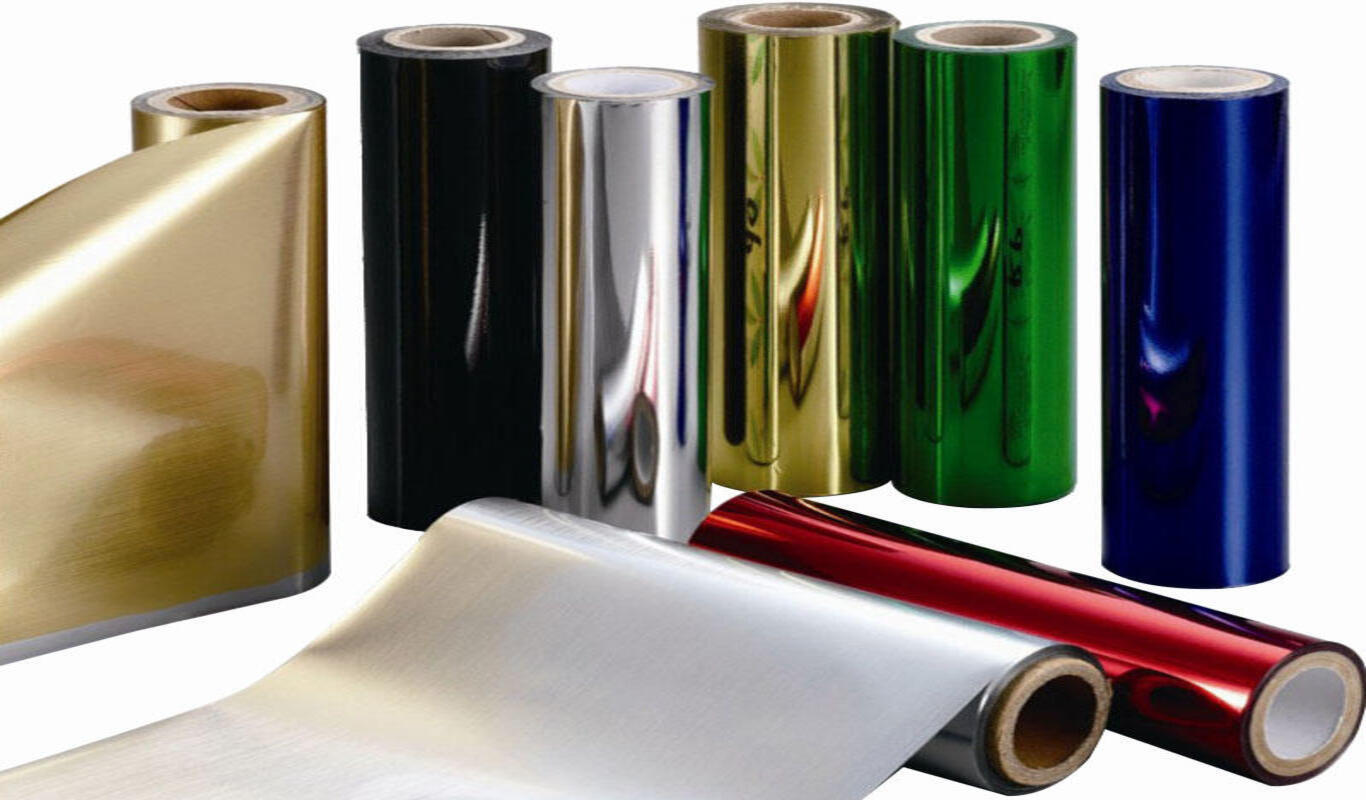

Even metalized PET films are not completely opaque. In the case of the incident light, this effect cannot be seen due to the silver reflective surface. This effect can be altered by printing, dyeing, painting, brushing, or embossing the PET film.

Effective protection against UV rays and thermal radiation

The highly reflective surface of metalized PET films can be used to create attractive optical effects in packaging as well as barriers to electromagnetic radiation.

Aluminum vapor-coated PET foil reflects not only visible and infrared light but also UV radiation. Aluminum coatings are different from silver or gold coatings used for similar purposes. In contrast to these metals, the degree of reflection of aluminum is largely independent of wavelength. The minimum value that is still above 85% is just above 800nm in the near-infrared range.

Influence of film thickness on PET reflection coefficient

The reflectance and optical density of metalized PET films increase with the thickness of the aluminum coating. Optical density (OD), measured as the logarithm of the incident optical radiation divided by the transmitted radiant energy, is typically between 0.25 and 3.5, which is satisfied for PET.

The thicker the aluminum layer, the higher the optical density and the lower the transparency. The degree of reflection is therefore approximately 66-99%, since an optical density of 0.3 corresponds to half the intensity of the transmitted radiation due to the logarithmic scale.

Typical applications for metallized PET films

Metallized PET films are suitable, for example, as a direct replacement for aluminium foils in packaging technology. At the same film thickness, PET met is characterized by higher tensile strength and flexural stiffness, which allows composites produced by metal vaporization to not wrinkle like aluminum foil.

However, aluminium foil also has advantages in specific packaging because, unlike PET metal film, it is opaque and guarantees absolute diffusion density. In general, foods wrapped in PET metallized film are therefore not as durable as those wrapped in aluminum foil. Therefore, PET film is more suitable for food with a short shelf life, which stays in the supermarket for a relatively short period of time before buyers can get it.

Further application possibilities for metallized PET films in the food packaging sector stem from the fact that very fine metal coatings change the conductivity of the film surface. This makes PET visible in metal detectors, but can also be used, for example, in the packaging of microwave cutlery with low moisture content, so that food can absorb more energy and heat up quickly.

In the case of building insulation, the positive effect of aluminium evaporation on the diffusion resistance as well as the reflection of thermal radiation is important. Compared to aluminium foil, PET met does not offer an absolute vapor barrier but has significantly higher mechanical resistance and better reflectivity.

Some of the properties of metallized PET films are described in detail above. If you plan to buy, please

contact us.

Polarfoil is a professional

custom insulation materials manufacturer. It has 3 vacuum coating machines and 8 PE extrusion coating production lines, guided by the 6S management system. The "pole foil" is made by vacuum coating. Low-density polyethylene-coated polyester film or low-density polyethylene-coated pure aluminum foil is one of its famous hot-selling products.