In today's world, sustainability has become a key consideration in every industry, including packaging. One area where significant progress has been made in sustainable packaging is the use of metallized PET films to coat PE. This article explores the sustainability aspects of this innovative packaging material, shedding light on its environmental impact, recycling options and future prospects.

What is Metallized PET Film?

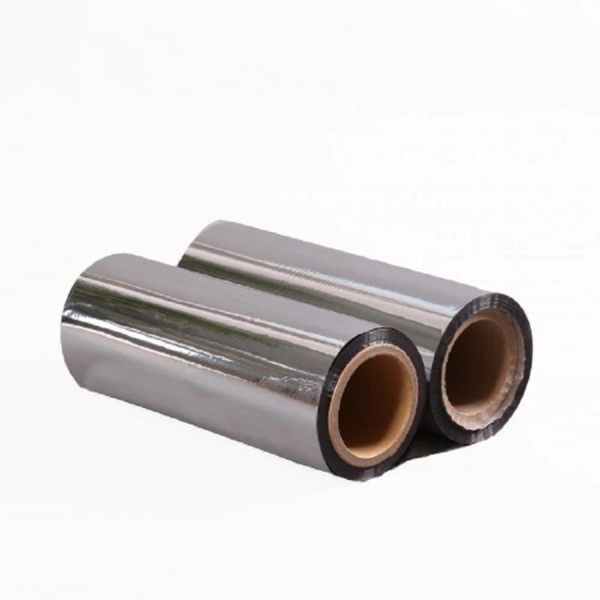

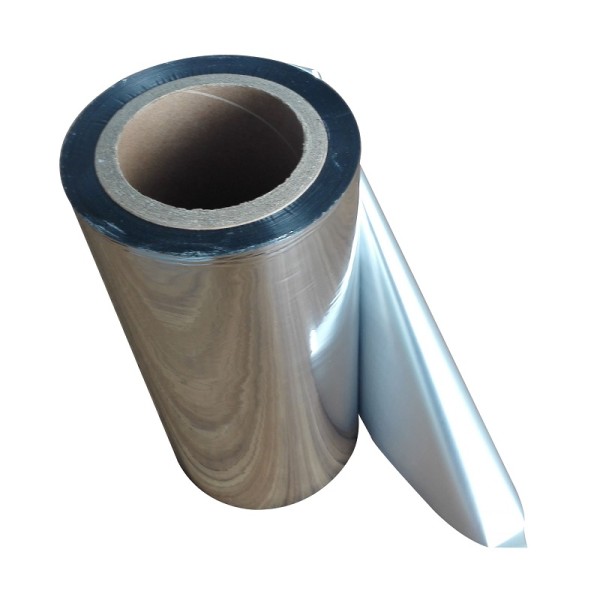

Metallized PET film is a thin, flexible material commonly used in packaging applications. It is made by evaporating a thin layer of metal (usually aluminium) and depositing it onto a PET film substrate. The resulting metallized films have reflective properties, provide a metallic appearance and enhanced barrier properties.

Coating Process

The coating process consists of applying a thin layer of metallized PET film on a PE (polyethene) substrate. This is achieved by various techniques such as lamination or extrusion coating. The metallized PET film acts as a barrier, protecting the PE substrate and enhancing its functionality.

Advantages of Metallized PET Coated PE

Metallized PET film-coated PE offers several advantages in terms of sustainability:

Enhanced Barrier Properties: Metallized PET film has excellent barrier properties to protect package contents from moisture, oxygen and UV radiation. This helps extend the shelf life of packaged products and reduces food waste.

Lightweight: Compared with traditional packaging materials, metallized PET film is lightweight, which reduces transportation costs and energy consumption.

Recyclability: Both PET and PE are widely recycled materials. Metallized PET film-coated PE can be recycled through established recycling streams, minimizing its environmental impact.

Energy Efficiency: The production process of metallized PET film-coated PE consumes less energy than alternative packaging materials, helping to reduce greenhouse gas emissions.

Environmental Impact of Metallized PET Film-coated PE

While metallized PET film-coated PE offers sustainability advantages, its environmental impact over its entire life cycle must be considered. Factors such as raw material procurement, production process, transportation and end-of-life disposal need to be evaluated.

Raw materials for the production of PET and PE are derived from fossil fuels and have associated environmental impacts. However, the lightweight nature of metallized PET film-coated PE helps to offset these effects during transportation and reduce overall carbon emissions.

Recycling and Disposal Options

Metallized PET film-coated PE can be recycled through established PET and PE recycling systems. However, the presence of metallized layers complicates the recycling process. Innovative recycling technologies are being developed to separate the metallized layer from the substrate, enabling efficient recycling.

Where recycling is not feasible, metallized PET film-coated PE can be incinerated to recover energy. Incineration facilities equipped with energy capture systems can convert materials into heat or electricity, minimizing waste.

Innovation in Sustainable Packaging

The need for sustainable packaging solutions has led to various innovations in the field of metallized PET film coated PE. Companies are actively exploring new technologies and methods to improve the sustainability of this packaging material. Some notable innovations include:

Bio-Based Films: Research is underway to develop bio-based alternatives to traditional PET films. These films utilize renewable resources such as plant-based polymers, reducing dependence on fossil fuels and minimizing environmental impact.

Water-Based Coatings: Traditional metallized thin-film coating processes often involve the use of solvents, which are harmful to the environment. Water-based coating technologies are being developed as an environmentally friendly alternative to reduce volatile organic compound (VOC) emissions.

Recyclable Metallized Films: Efforts are underway to develop metallized films that are more easily recyclable. Innovations include the use of metal alloys that can be more effectively separated from film substrates, thereby increasing recovery rates.

Circular Economy Initiative: Collaboration among packaging industry stakeholders is essential to achieve a circular economy for metallized PET film-coated PE. Initiatives such as collection programs, partnerships with recycling facilities, and consumer education campaigns are being implemented to promote proper disposal and recycling practices.

Case Study: Sustainable Application of Metallized PET Film Coated PE

A few real-world examples highlight the sustainable application of metallized PET film-coated PE:

Sustainable Food Packaging: Metallized PET film-coated PE is widely used in the food industry for packaging perishable goods. Its barrier properties help preserve product freshness and reduce food waste. In addition, its lightweight helps to reduce transport emissions.

Sustainable Beauty and Personal Care Packaging: Metallized PET film-coated PE is also used in the beauty and personal care industry for products such as shampoos, lotions and cosmetics. The material's protective properties ensure product integrity, while its recyclability aligns with the industry's sustainability goals.

Sustainable Medical Packaging: Metallized PET film-coated PE plays a vital role in the medical sector, where aseptic packaging is crucial. Its barrier properties help maintain the integrity and safety of medical devices, pharmaceuticals and diagnostic kits.

Metallized PET film-coated PE offers sustainable packaging solutions with enhanced barrier properties, recyclability and lightweight properties. It helps reduce food waste, lower carbon emissions and promote a circular economy. If you want to buy Metallized PET Film Coated PE, welcome to contact us.

PENGYUAN is a professional custom professional VMPET coated PE manufacturer. We have 3 vacuum coating machines and 8 PE extrusion coating production lines, guided by 6S management system. As the largest extrusion coating base in China, the company has obtained ISO9001, ISO14001, ISO45001 production standards for the whole system. Our experts have years of experience and can help you research your target market. In addition, they will be there to help you determine whether your product meets the needs of the relevant market. In this way, we will ensure that your business makes the best decisions.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.

Order samples

Learn more from our FAQ

- Which to choose Aluminum foil coated PE or Metalized pet film coated PE ?

It depends on what product to be made in final procedure. Aluminum foil coated pe is with at least 97% reflectivity, it can be bonded to EPE foam but also most of time for laminated with bubble. Metalized pet film coated PE with lower reflectivity ,but it is with strong surface.

- I am a insulated liner/bag manufacturer,what product do you suggest?

There maybe bubble lamination machines and heating pressure lamination machines in your factory, we suggest Aluminum foil 7mic+PE20mic, and Metalized PET film12mic+PE15mic.

- If i would like to get a quote ,what information shall i need to know first?

You are request to telling application, material structure,thickness and roll width and quantity.

TO GET A FREE SAMPLE

Please fill in the form below and we will response to you within 24 hours.

- Phone

- *Title

- *Content

ZHEJIANG PENGYUAN is the leader of extrusion coating, the professional manufacturer & supplier of PolarFoil

Navigation

News

- Application of Aluminum Foil in Agriculture: Improving Crop YieldAluminum foil has proven to be an effective tool in increasing crop yields. Below we explore the various ways aluminum foil is used in agriculture and the benefits it brings to farming.

- New Study Reveals Benefits of Foil-Coated PE in ConstructionFoil-coated PE enables more efficient and sustainable building practices. In this article, we will delve into the results of this study and explore the advantages of foil-coated PE and its applications.