In today's world where environmental sustainability is becoming increasingly important, finding environmentally friendly packaging solutions is critical for businesses. One sustainable packaging option that is gaining attention is PE (polyethylene) coated with aluminum foil. With its unique properties and versatility, this alternative offers several advantages in maintaining product quality, reducing waste, and minimizing environmental impact. In this article, we explore the advantages of using foil-coated PE as a sustainable packaging solution.

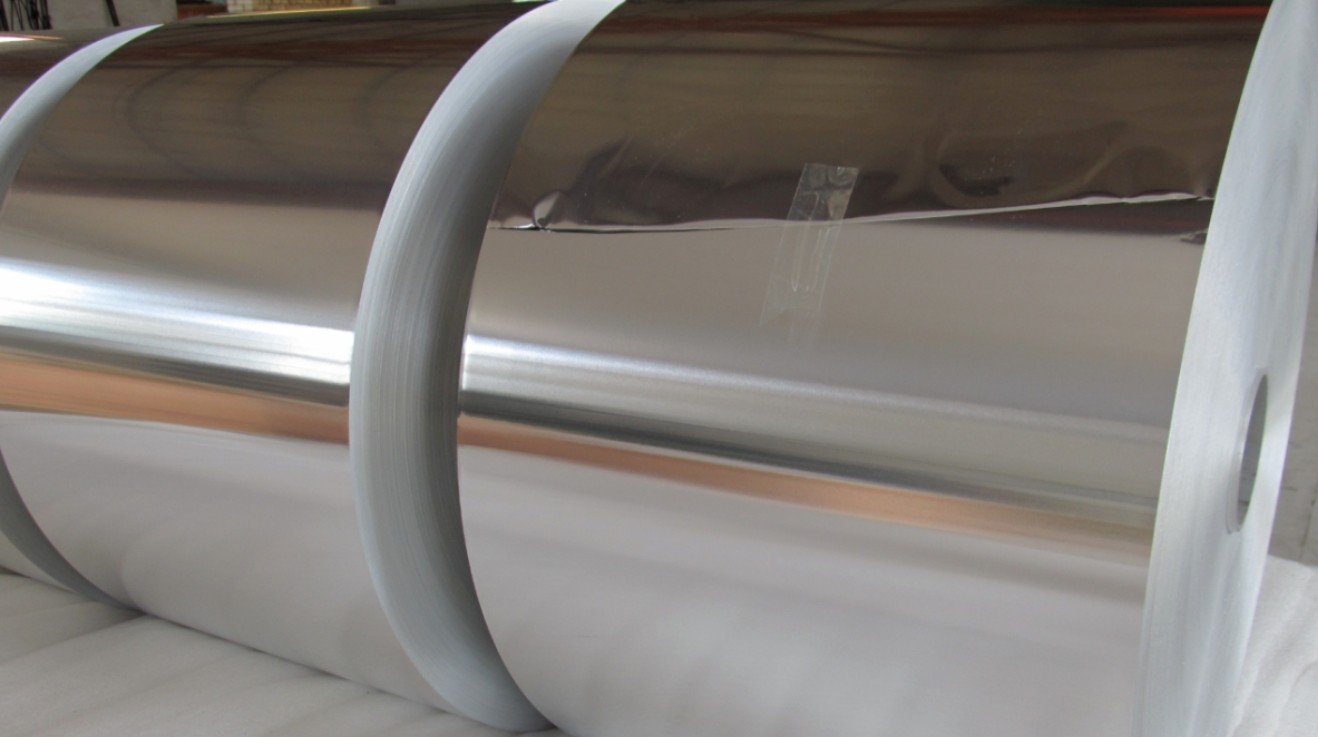

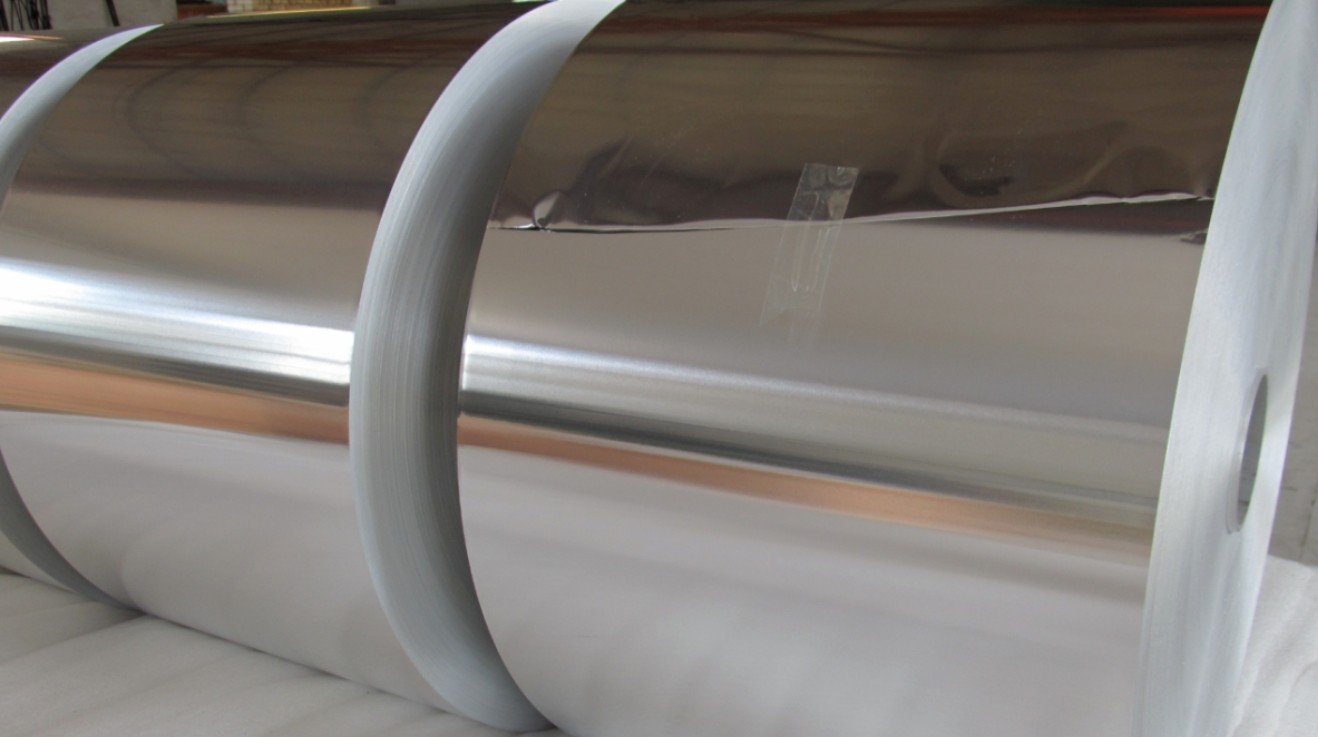

Aluminum-coated PE is a packaging material that combines the strength and flexibility of polyethylene with the barrier and conductivity of aluminum foil. This combination makes it an excellent choice for various industries looking for sustainable packaging solutions.

The Benefits of Aluminum Foil PE

1. Product Protection and Storage

Foil-coated PE provides excellent protection against moisture, light, and oxygen. It forms a barrier that protects the product from external elements, prevents spoilage, and extends its shelf life.

2. Lightweight and Durable

Despite its excellent protective properties, foil-coated PE is lightweight, making it an energy-efficient transport option. Its durability ensures that the packaging can withstand handling and shipping without compromising the integrity of the product.

3. Humidity and Heat Resistance

The combination of aluminum foil and PE provides excellent heat resistance, enabling the packaging to withstand high temperatures. Plus, it's moisture-resistant to keep the contents from being damaged or contaminated.

4. Barrier Properties

PE coated with aluminum foil acts as a reliable barrier against gases, odors, and microorganisms. It maintains the quality of the packaged product, ensuring it reaches the consumer in top condition.

5. Recyclability and Environmental Impact

One of the main advantages of foil-coated PE is its recyclability. This material can be easily separated and recycled, reducing the overall impact on the environment. Furthermore, using this sustainable packaging solution reduces the consumption of non-renewable resources compared to conventional packaging materials.

Application of Aluminum Foil Wrapped PE

1. Food and Beverage Industry

The food and beverage industry greatly benefits from the use of foil-coated PE for sustainable packaging. It ensures the freshness and quality of perishable commodities such as fruit, vegetables, dairy products, and beverages. The barrier properties of foil-coated PE protect against external elements such as air, light, and moisture, thereby maintaining the flavor, texture, and nutritional value of packaged foods.

2. Pharmaceutical and Medical Sector

In the pharmaceutical and medical fields, maintaining product integrity and safety is of paramount importance. Aluminum foil-coated PE is an excellent packaging solution for pharmaceuticals, medical devices, and healthcare products. It provides a protective barrier against contamination, moisture, and temperature fluctuations, ensuring the effectiveness and longevity of closed items.

3. Personal Care and Cosmetics

The personal care and cosmetics industries also benefit from the use of sustainable packaging solutions. Foil-coated PE packaging is ideal for products such as lotions, creams, and ointments as it protects them from light and air, which can lead to degradation and reduced effectiveness. Plus, it prevents leaks, ensuring the product remains intact during shipping and storage.

4. Electronics and Technology

Electronics and technology products require safe and protective packaging due to their fragile nature. Foil-coated PE provides excellent ESD protection, protecting sensitive electronic components from static electricity and potential damage. It also keeps out moisture and dust, ensuring the product reaches the consumer in perfect working condition.

Challenges and Limitations

While PE coated with aluminum foil has many advantages, there are some challenges and limitations that need to be considered. Production and processing costs can be higher compared to traditional packaging materials. Additionally, recycling infrastructure and practices may vary in different regions, affecting the recyclability of materials. It is important to address these challenges and work to optimize production, recycling and disposal processes to improve the sustainability of foil-coated PE packaging.

Future Outlook

Demand for sustainable packaging solutions is expected to grow as more businesses prioritize environmental responsibility. Foil-coated PE shows great potential as a viable alternative to traditional packaging materials. With continuous research and development, advancements in technology and manufacturing processes can further enhance its performance and increase its adoption across various industries.

Foil-coated PE offers sustainable packaging solutions that balance product protection, recyclability, and environmental impact. Its unique combination of polyethylene and aluminum foil provides a lightweight, durable, and high-barrier packaging material that meets the needs of industries such as food and beverage, pharmaceuticals, personal care, cosmetics, and electronics. By adopting foil-coated PE, businesses can contribute to reducing waste, conserving resources, and promoting a greener future.

The above introduces the sustainability of aluminum foil-coated PE, if you want to know more or want to buy aluminum foil-coated PE, please

contact us.

PENGYUAN is a professional

custom aluminum foil manufacturer. We have 3 vacuum coating machines and 8 PE extrusion coating production lines, guided by the 6S management system. As the largest extruder coating base in China, the company has obtained ISO9001, ISO14001, and ISO45001 production standards for the whole system. Through wider and deeper cooperation, Pengyuan will continue to focus on the R&D and manufacturing of extrusion coating technology. We are committed to becoming an advanced provider of energy-saving new materials and solutions.